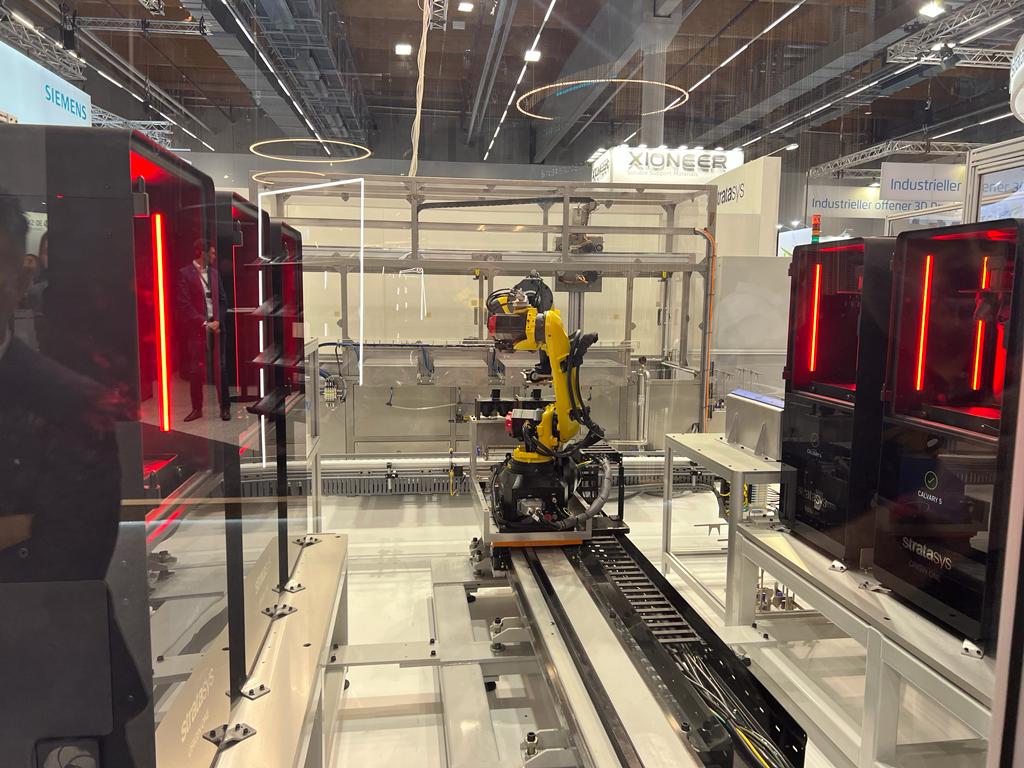

Stratasys unveils new fully-automated Origin 3D printing production cell at Formnext

The 3D Printing Business Awards 2022 shortlists are actually accessible for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

3D printer OEM Stratasys has demonstrated a brand new fully-integrated 3D printing and post-processing platform on the Formnext commerce present.

Stratasys’ P3 Automated Manufacturing Cell incorporates a string of Origin One programs, in addition to robotics, conveyors and half ending gear. As soon as prints are prepared, the cell’s mechanical arm is ready to accumulate and transport the related construct plate to an in-built post-processing facility, with the UV curing and drying performance to scrub, rinse and treatment them as essential.

Developed with Calvary Robotics, the setup was initially designed to point out the way it’s attainable to harness robotics as a method of driving down manufacturing prices and scaling 3D printing. That stated, the system can also be instantly configurable to buyer wants, and Stratasys’ companion has stated it’s hoping that the drawing consideration to the setup at Formnext, will entice new clientele to its automated manufacturing portfolio.

Stratasys’ P3 Automated Manufacturing Cell

Debuted at Formnext, Stratasys’ demonstrator manufacturing cell revolves across the P3 know-how purchased by way of its acquisition of Origin practically two years in the past. Origin’s Programmable Photopolymerization (P3) course of permits for the printing of components with voxel-level management, in a method that allows customers to extract totally different mechanical performances from a fabric, and customise components for particular purposes.

The P3-powered Origin One can also be constructed to facilitate manufacturing at scale. Origin says its system does so by way of pairing “unmatched part-to-part consistency” with a excessive throughput, and the incorporation of a modular design which is each optimized for batch manufacturing, and allows capability to be elevated the place wanted.

With its P3 Automated Manufacturing Cell, Stratasys is now trying to completely notice the machine’s high-throughput promise, by way of its incorporation right into a fully-automatic manufacturing workflow. In apply, the setup operates with a robotic arm, which picks up construct plates filled with prints on demand, and transfers them for post-processing or sorting by way of a winding conveyor.

As soon as a cycle has been accomplished, the platform’s robotic arm is then able to cleansing, emptying and returning the construct plate to the related printer, prepared for the subsequent batch to start. Whereas Stratasys says the cell has been constructed as a part of a “demonstration mission” to “enhance the effectivity of working fleets of Origin One 3D printers,” Calvary Robotics does supply comparable setups on a business foundation.

Stratasys unveiled its uniquely-integrated platform as a part of its ‘Let’s Speak Manufacturing’ show at Formnext. This additionally noticed the agency announce the validation of latest supplies from the likes Arkema, Victrex and Covestro for its programs, and the introduction of the ‘UILA’ EV idea, a partially-3D printed four-wheeled two-seater designed as a sustainable transport resolution.

“During the last two and half years, our focus has expanded from build up our {hardware} portfolio to working with key trade companions to develop a variety of use-case-specific options,” stated Andy Langfeld, President of EMEA at Stratasys. “These full options embody {hardware}, software program, supplies, and companies that create new enterprise alternatives for our prospects.”

“We proceed to speed up cutting-edge developments in additive manufacturing and advance our technique of offering the very best and most full polymer 3D printing portfolio within the trade.”

After all, Stratasys’ P3 demonstrator isn’t its first to be unveiled at a significant commerce present. In 2017, Stratasys’ Steady Construct 3D Demonstrator was launched at Fast+TCT. Whereas designed to work with FDM programs relatively than resin ones, the setup was in-built pursuit of the identical purpose: chaining machines to unlock the fully-automated 3D printing of components.

Elsewhere within the trade, 3D Techniques’ Determine 4 Manufacturing programs may also be linked right into a 3D printing manufacturing line, with only one management unit working a number of cells without delay. In line with the corporate, its machines enable customers to “develop capability alongside demand,” from a standalone printer for speedy prototyping and low quantity manufacturing, to a “fully-automated, built-in manufacturing unit resolution.”

Comply with this hyperlink for all of the Formnext 2022 information.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business e-newsletter or observe us on Twitter or liking our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? that includes dialogue, debriefs, video shorts and webinar replays.

Are you in search of a job within the additive manufacturing trade? Go to 3D Printing Jobs for a choice of roles within the trade.

Featured picture reveals Stratasys’ P3 Automated Manufacturing Cell at Formnext. Picture by Mael Duportal.