Is It Time to Unify Your Print Room?

As PSPs diversify their companies, they’re managing a spread of job varieties throughout totally different digital printing applied sciences from a number of distributors. On this article, sponsored by Fiery, John Henze from Fiery discusses how PSPs can embrace diversification and create a unified print room by leveraging RIP software program.

Watch the video

It’s no secret, and never new, that many print service suppliers are diversifying their enterprise to remain aggressive and develop. Industrial printers are including large-format choices, and large-format companies are shifting into specialty print functions. Print operators at the moment are managing a spread of print jobs throughout a number of printers, presses, and ending tools from totally different producers. One key to success is unifying print rooms with only one centralized job administration workflow that transcends print applied sciences, printer manufacturers, and fashions — consolidating all print manufacturing processes.

We sat down with John Henze, VP of Gross sales and Advertising at Fiery, LLC, the main impartial supplier of digital entrance ends (DFEs), to debate how PSPs can unite their digital print rooms as they increase into new markets with new tools.

WhatTheyThink: As PSPs look to increase and develop their companies, the place are the largest alternatives?

John Henze: By far, essentially the most vital progress alternatives for PSPs lie in diversifying into print merchandise that complement what they already produce or fall into strong-growth areas.

John Henze: By far, essentially the most vital progress alternatives for PSPs lie in diversifying into print merchandise that complement what they already produce or fall into strong-growth areas.

What I imply by “complement” is that if a PSP serves the healthcare sector by producing leaflets and flyers, likelihood is the identical buyer will want posters and signage to help the marketing campaign or initiative. Most clients would like to take care of only one provider, particularly if coloration consistency is a precedence for them. This is the reason many industrial printers have moved into massive format print, it’s a logical subsequent step.

One other progress space that continues to be very robust is personalised printed merchandise and specialty manufacturing. That’s something from printing straight onto clothes to engraving onto merchandise, or printing labels, folding cartons and far more.

WTT: What ought to PSPs contemplate earlier than coming into new print markets utilizing new applied sciences?

JH: Sometimes, PSPs do an important job assessing the market they’re coming into and the expansion potential it’ll convey. Plus, they do a improbable job researching the capabilities of a brand new printer to make sure that it will possibly do what they want. These are important enterprise steps.

Nonetheless, many print homeowners overlook how they are going to ‘drive’ their new expertise investments and combine them into present workflows. Little doubt the brand new printer, imaging, or ending expertise comes with software program, however PSPs ought to go additional and ask how the software program or server maximizes their new funding. Will it combine with their present software program investments and workflows? What’s the studying curve of the software program?

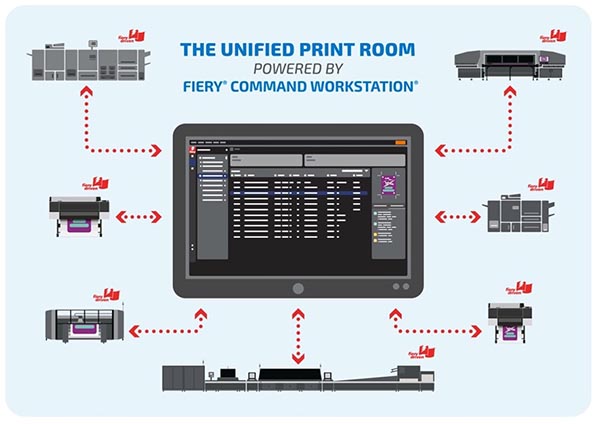

With so many various print applied sciences and producers, one other problem PSPs face is determining how new print investments match with their present tools to handle their print room effectively. How can printers convey uniformity to their print room, making it simpler for workers to handle print jobs throughout all digital print investments – particularly as they increase into new applied sciences? At Fiery, we name this growing a unified print room.

These are vital questions print homeowners want to consider prematurely in the event that they need to hit the bottom operating with new investments and begin profiting instantly.

WTT: How can a PSP unify their print room?

JH: The concept of a unified print room is about standardizing what manages your digital print job manufacturing—it doesn’t matter what the print expertise or producer. This makes the introduction of recent printers and presses simpler.

If the workflow is understood, then worker coaching is partly executed. That is notably vital whereas we’re nonetheless within the local weather of restricted expert sources within the print trade. For instance, if the software program driving new printers is acquainted (which Fiery expertise tends to be), employees can concentrate on what the brand new expertise can produce. Principally, the brand new printer can simply slot straight in and do what it was bought to do, which is increase the choices of the PSP.

To realize a unified print room, all print manufacturing is taken care of by the identical RIP and workflow resolution. Having one centralized interface to handle all print manufacturing makes it simpler to onboard new employees, practice staff on new press investments, and produce high-quality jobs nearly instantly for max return on funding.

WTT: How is Fiery main the way in which in unifying the print room? And what makes Fiery’s method distinctive available in the market?

JH: Fiery DFEs are the one RIP and workflow options that drive cutsheet toner presses, highspeed inkjet printers, plus vast to superwide units. This makes us uniquely positioned to assist unify the print room. No different software program vendor has this similar attain.

For instance, various DFEs are offered by printer producers, however they solely work with their very own tools. The software program is offered as a result of it’s wanted to make the tools run. Nonetheless, when PSPs have to increase into new areas or use totally different producers’ print expertise, this could result in many various DFEs with totally different workflows in a single print room, or worse, PSPs being trapped into one-manufacturer options. As an impartial supplier that transcends producers, Fiery gives distinctive benefits and allows PSPs to take a position and develop their companies whereas maintaining acquainted workflows.

After all, print engines differ throughout applied sciences and print producers. Every Fiery server leverages our core RIP innovation and is optimized for a particular print engine/producer catering to totally different screening necessities, tools innovation, methods to switch print information, and extra. What ties all our Fiery DFEs collectively and makes them uniform is Fiery Command WorkStation job administration software program.

Fiery Command WorkStation is the “window in and conductor of” manufacturing. It’s the central interface the place you handle jobs for print, apply coloration administration, and schedule jobs for the simplest use of your Fiery pushed sources. It additionally provides you a chook’s eye view of all of your manufacturing—from one location.

WTT: Are there different Fiery instruments that work throughout totally different press varieties that may assist streamline print room operations?

JH: There are. We all know the top buyer expects constant coloration throughout printed merchandise – whatever the print expertise used. All of it has to match. Fiery Shade Profiler Suite is the colour administration resolution for all Fiery Pushed™ printers. It’s principally the device that gives built-in coloration administration and management for something that’s pushed by a Fiery DFE.

There are large variations in printer gamuts throughout print applied sciences, and matching outcomes wants good coloration administration. Having Fiery Shade Profiler Suite throughout all Fiery Pushed expertise doesn’t alter the legal guidelines of coloration science — it will possibly’t make a printer’s gamut greater. As an alternative, it supplies one coloration toolset that works throughout Fiery pushed units to determine a unifying course of for profile creation, inspection, modifying, coloration high quality assurance, and output enhancement. This makes on a regular basis coloration administration duties simpler and extra routine, even for much less skilled customers, leading to higher coloration.

WTT: Lastly, what recommendation do you’ve gotten for PSPs as they give the impression of being to diversify to develop their companies?

JH: That’s a straightforward one, “go for it”. If you concentrate on it, diversifying is what Fiery frequently does by way of acquisitions, investments, and innovation to maintain our enterprise robust and on the forefront of the place we sit.

Secondly, don’t underestimate the impression of how new expertise suits into what you already do and the way you do it. If it is advisable to adapt your workflows to accommodate a brand new printer, incur further coaching overheads, and develop new help agreements and procedures, this could take away among the advantages of diversifying.

As PSPs look to increase, do your market evaluation, printer analysis, and workflow match. And keep in mind, Fiery Command WorkStation may also help unify job administration and manufacturing workflows throughout all of your Fiery pushed servers to achieve operational efficiencies and improve productiveness. Most significantly, it will possibly play an enormous half within the success of what you are promoting progress.

For PSPs who need to be taught extra about workflow match or unifying their print rooms, we provide free sources accessible at Fiery Studying and Fiery Communities, and Fiery customers can obtain the most recent Fiery Command WorkStation at the moment.