S’pore’s Craft Health the first 3D-printing medicine firm in SEA

Goh Wei Jiang, Lim Seng Han and Lim Seng Han are pharmacists who have seen a common problem among elderly patients. An overwhelming number of medications are being prescribed for multiple diagnoses – mainly diabetes, hypertension, and high cholesterol.

After each visit, these patients would be discharged from the hospital or nearby polyclinic with bags of pills and a complex regimen to follow. This often caused confusion and made mistakes.

The duo didn’t stop at observing the problem. They decided to go beyond academic publishing and solve the problem during their final PhD studies at the National University of Singapore.

Seng Han’s expertise in 3D printing sparked an idea: Could they combine the active ingredients of various medications and put them altogether in a single pill?

The couple later received a small grant for research to prove that their theory actually works.

After completing their respective theses, the students enrolled into the NUS Graduate Research Innovation Programme. This three-month structured curriculum guides participants through a startup.

“Essentially, GRIP is like an incubator,” explained Wei Jiang. “We were the first cohort of participants when it was launched in 2018. It gave us ample opportunities to speak with many stakeholders – hospital administrators, doctors, clinicians, pharmacists, patients, among others.”

“After weighing all the evidence, we concluded that both the demand for better medication management and solution (3D printing medicine) are real, and thus, Craft Health was born.”

It is not easy to make a new technology function.

Craft Health is set to transform the pharmaceutical industry.

Although promising, Wei Jiang acknowledged that it was difficult to attract investors at the beginning. Many people were still unfamiliar with 3D printing in 2019.

“Most of the time, it’s just Seng Han and I with our laptops. We didn’t have much to show and convince people. So, they were sceptical about what we could offer,” he added.

Many investors were thrilled to see Craft Health as the first and only 3D-printed medicines and nutraceutical business in Singapore and Southeast Asia. However, the cautious ones wanted to know if 3D printed medicine is something that had been done before so they could pattern match Craft Health’s success rate.

Ironically, out of the 80 potential investors Wei Jiang spoke to, only one was willing take a leap in faith for their company. Just when they thought things were moving in the right direction the COVID-19 pandemic struck.

At the beginning, there was a lot of naivety. It was our belief that 3D printing technology is the only problem. Turns out, this is just the beginning.

– Goh Wei Jin, co-founder Craft Health

Seng Han and Wei Jiang quickly discovered that there are more challenges in managing the logistics for mass production of 3D printed medicines. They also need to educate potential clients about the key benefits of 3D printing and ensure Craft Health delivers all its promises safely and efficiently.

But Craft Health’s secret weapon lies in the chain of workflow that they had developed to support the entire 3D printing drug delivery process.

One-stop shop for 3D printing medicine and supplements

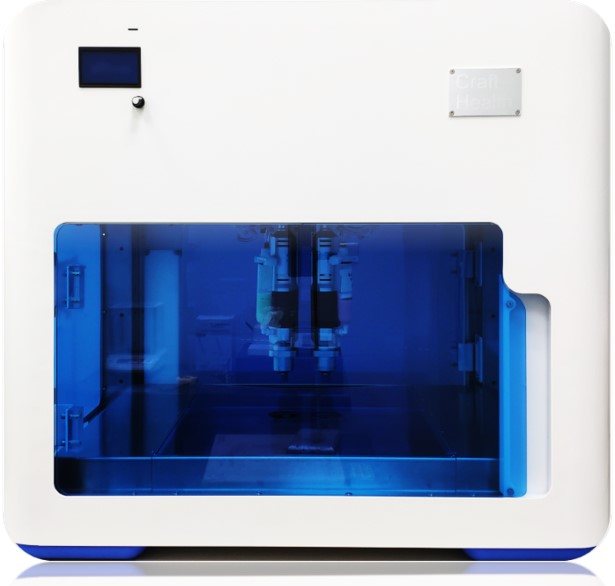

It starts with 3D printers (Craft).Make). These hardwares can be used to 3D print at room temperature and pressure without heat or UV light.

This allows for different active ingredients to be combined in one pill. Craft is also included.Control Software that tells 3D printers how to correctly print the medication in the correct way.

Craft Health can tailor the active ingredients or release profile of medication to meet specific patient requirements, whether they are for immediate release or long-term release. As such, CraftBlends is the “recipe book” that carefully cooks up different formulations.

Craft generates and uses all information.MakeCraftControlCraftBlends CraftDatabase. This archive system – one of the first in the world – allows Wei Jiang and Seng Han to better understand the interplay of various materials and factors, so they can 3D print more specialised or even personalised medicines.

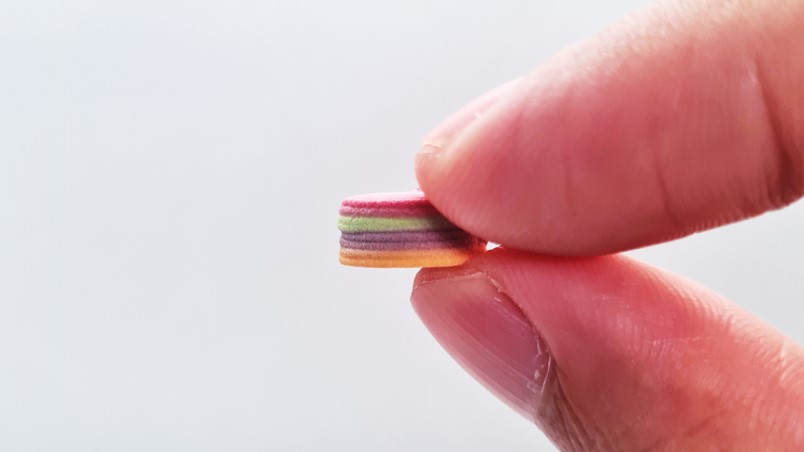

Certain active ingredients, for example, can make medications unpleasant tasting. Craft Health can 3D print a multi-layered pill or a capsule that contains another pill to mask its taste. The outer layer of the multilayer pill can also be customized to protect against acidic stomach contents and allow for the release of intestine content.

Craft Health is simultaneously expanding its nutraceutical arm.

CraftBeads 3D-printed granules can be customized to suit your needs. Craft is a better alternative to buying vitamins from the shelf and eating them one at a time.Beads can mix and match to create custom blends based on individuals’ supplementary needs.

Craft on the other sideDelights It is a side project 3D printed gummy that was initially intended to be a sweet solution for paediatric patients but quickly gained fans among adults.

We can also incorporate probiotics into these gummies because they are 3D printed without the use of heat or UV light. This technique allows for different shapes, sizes, geometrics, and tastes. That’s probably why people are excited about it, as they can see very highly personalised gummies being made.

– Goh Wei Jin, co-founder Craft Health

The regulatory hurdle to 3D printing medicines

There is currently no regulatory framework for 3D printed medicines in Singapore and around the world.

It is unclear how drug approvals are made in general. Most often, health authorities will approve a particular brand of medication when it comes in a certain dose. Any changes in active ingredients or dosage require a new consent.

In the case of 3D printing medications when the combination of active ingredients and dosage becomes limitless, it’s impossible to officially register and green light every mix. Craft Health plans to overcome this hurdle by using the compounding route.

According to Wei Jiang, compounding is a pharmaceutical practice that’s not very common in Singapore.

Patients can ask for certain ingredients to be removed or added to a medication they take due to allergies or other medical reasons. In that case, pharmacists will have to specially “compound” the drugs for the patients.

Craft Health plans to conduct a small clinical trial with a local hospital at the beginning of next year. They want to prove that it’s just as efficacious for patients to take a 3D printed pill containing active ingredients from three different types of medications versus taking them separately.

“It’s a very low bar for us to cross,” Wei Jiang said confidently. “But our rationale is to provide some preliminary evidence to the doctors that our products are safe and effective.”

Craft Health plans to eventually develop a list of 3D-printed medicines that doctors can use to prescribe the appropriate medicine.

Take a less traveled road

While it may still be years before Craft Health, and probably the whole 3D printing medication industry, arrives at their ultimate goals, the founders are glad it’s emerging as a pioneering and dominant player in the field.

“Establishing Craft Health as a deeptech spinoff from NUS is already a huge advantage. This shows that our technology is being supported by a trusted institution. There are some validations that this is doable,” noted Wei Jiang.

It’s exciting, Wei Jiang admitted that being an entrepreneur is not as thrilling as it sounds. However, he also acknowledged that being an entrepreneur can expose him to many uncertainties that he wouldn’t have experienced while working as a pharmacist.

Entrepreneurship is all about taking on everything. Everything must be done, even fixing the aircon in your office.

– Goh Wei Jin, co-founder Craft Health

Whether it’s the 3D printing technology itself, or the operation, business, and legal side of things, Wei Jiang and Seng Han had learnt a lot in the past four years, and they learnt them fast despite the steeo growth curve.

The 3D printing of pharmaceutical and nutraceutical products holds incredible potential, just like the endless number of prescription combinations 3D printing allows for. It is impossible to keep up with the pace of technological advancement.

Image credit: National University of Singapore