Sustainability in the spotlight as EOS and Siemens both showcase green tech at Formnext

The 3D Printing Business Awards 2022 shortlists at the moment are accessible for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

Industrial manufacturing agency Siemens and powder mattress fusion (PBF) 3D printer developer EOS have each debuted sustainable new 3D printing purposes, Siemens, and powders, EOS, on the Formnext commerce present.

Whereas Siemens has demonstrated how 3D printing’s inherent design freedoms might help scale back the footprint of automotive grippers, EOS has launched two eco-friendly supplies. Historically petrol-based, the agency’s carbon-reduced PA 2200 now accommodates practically 45% much less CO2 than earlier than. EOS has additionally launched a climate-neutral PA 1101 that manages to be bio-based with out compromising on high quality.

“We at present consider the local weather influence of each facet of business 3D printing to create transparency of the established order,” mentioned Björn Hannappel, Head of Sustainability at EOS. “We additionally consider and enhance manufacturing effectivity. For our new environmentally inexperienced supplies, we scale back greenhouse fuel emissions as a lot as potential. And we put money into gold normal local weather safety initiatives to offset unavoidable greenhouse fuel emissions.”

“Sustainability is not only a key driver for us however has additionally turn out to be more and more vital to our prospects as effectively.”

Siemens furthers inexperienced 3D printing

For producers to realize their local weather targets, Siemens says they need to think about all the worth chain of a product transparently. At Formnext, the agency confirmed how such an strategy could be deployed in observe through a collection of 3D printing purposes that yielded useful resource financial savings whereas serving to companies scale back their carbon footprints.

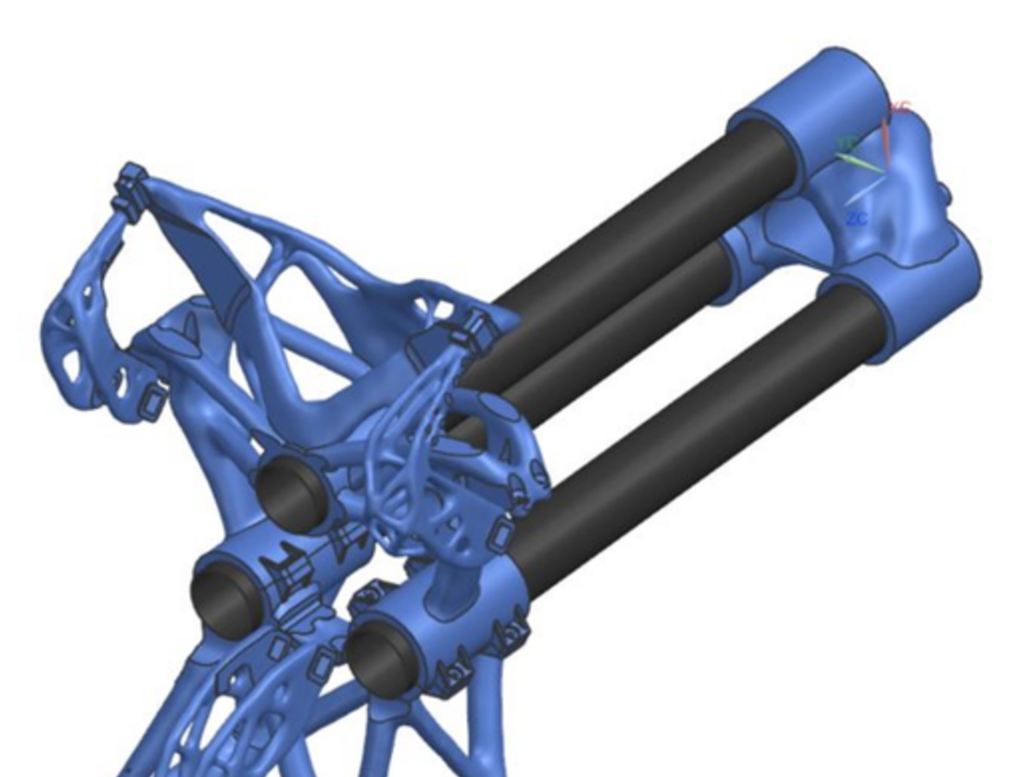

Using its NX for AM digital course of chain and Product Carbon Footprint Calculator, Siemens has discovered it potential to chop the mass of an automotive dealing with bot’s grippers by 64%. Doing so not solely yielded a topologically-optimized half, which was 73% cheaper to provide than earlier than however one with an 82% decrease CO2 footprint. As a result of gripper’s a lot smaller measurement, the end-user has even been in a position to start utilizing smaller manufacturing facility robots in a means that has minimize its associated vitality invoice by 54%.

In a second use case unveiled on the present, Siemens confirmed the way it has labored with Genera to enhance the vitality consumption of its 3D printers. Particularly, utilizing Siemens Advanta’s AM Digital Manufacturing unit Planning toolbox, the companies have been in a position to establish methods of bettering system vitality administration, via manufacturing simulations. It’s thought vitality financial savings may quantity to 25-30% per half.

Siemens’ third software demo at Formnext confirmed how 3D printing infrastructure may deliver huge sustainability advantages. As a part of the EU SeaBioComp venture, CEAD and Poly Merchandise have 3D printed flax harbor fenders designed to make sure that quay partitions don’t injury ships in port. These are often constituted of plastics that put on, dropping microplastics into the ocean. By printing and milling their fenders, the group made them extra exactly from biodegradables.

EOS’ new eco-friendly supplies

For EOS, materials sourcing, consumption, and reusability are crucial to minimizing powder waste. In the case of sourcing, the agency focuses on discovering the best powders for 3D printing earlier than turning to how they are often created and certified for EOS methods, with the assumption that via the usage of uncooked supplies and better manufacturing effectivity, it’s potential to drive down scrap produced.

In step with this philosophy, EOS has launched PA 2200 CarbonReduced, a cloth that has been developed utilizing a extra environment friendly manufacturing course of, successfully reducing its carbon footprint. At Formnext, the corporate additionally launched PA 1101 ClimateNeutral. The bio-based powder has a smaller footprint than petrol polymers too, and ships with a certification proving its carbon-offsetting credentials.

In addition to new supplies, EOS showcased the FORMIGA P 110 FDR 3D printer through the present. Not like the agency’s present providing, the system makes use of a CO laser with a spotlight diameter twice as small as present SLS applied sciences to print components with extraordinarily high-quality surfaces and a minimal wall thickness of simply 0.22 mm. As such, it’s thought the machine may have purposes in areas the place precision engineering is significant, just like the creation of optics, and small gears, valves, pipes, plugs or electronics.

Concentrating on sustainable supplies

Growing sustainable 3D printing supplies continues to be a key goal for producers and researchers throughout the trade. Earlier this yr, Braskem’s first sustainable filament vary was launched at Speedy+TCT, consisting of bio-based ethylene vinyl acetate (EVA), recycled polyethylene (PE) and polypropylene (PP).

Over in Estonia, Filaret has begun turning cigarette butts into filament. Having arrange bins alongside the coast of a seaside within the nation’s capital Tallinn, it plans to make use of them to gather waste which it might probably convert it right into a compostable 3D printing materials.

At Formnext, the Desktop Steel Forust System was additionally debuted, a machine able to printing upcycled sawdust into practical, end-use picket components. The method behind the unit was first unveiled final yr, however the firm has since refined the know-how and is now bringing it to market.

Observe this hyperlink for all of the Formnext 2022 information.

To remain updated with the most recent 3D printing information, don’t overlook to subscribe to the 3D Printing Business publication or observe us on Twitter or liking our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? that includes dialogue, debriefs, video shorts and webinar replays.

Are you searching for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a collection of roles within the trade.

Featured picture reveals a Siemens-redesigned 3D printed robotic gripper. Picture through Siemens.